Stainless steel wire materials can be used to create fall protection barriers that look light and airy, while being highly robust, durable and compliant.

But these tensile structures can go further in sustainable projects, helping to reduce emissions and environmental impact.

This is achieved through the sustainability and efficiency of the materials and the building processes.

Here’s how.

Combining sustainability and efficiency

In many of our installations, we use Jakob stainless steel wire rope cables and Webnet mesh.

These materials are highly sustainable. Webnet is made from an average of 70% recycled content in facilities that run on 90 to 100% renewable energy. This makes it highly suited to projects with sustainability goals.

Webnet can also be recycled and repurposed after use, which reduces waste and adds to the material’s long-term usefulness.

Maximising material efficiency

Stainless steel wire materials can provide a very efficient solution. For example, Webnet’s large span capacity (up to 6,000 sqm between posts) can substantially reduce material requirements. This in turn helps lower not only costs but also the environmental impact that comes with material production, handling, travel and labour.

This wide span capacity is demonstrated at the rooftop sports court at St Patrick’s College in Sydney, where the mesh barrier provides a very large space free of columns.

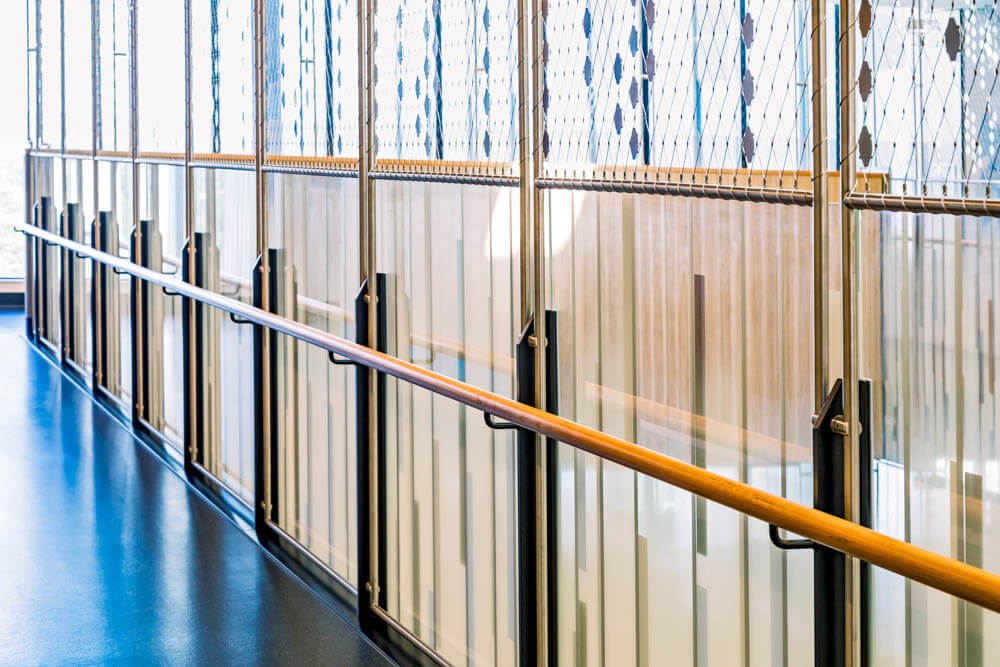

Stainless steel wire can also be configured into vertical cables to create flexible full-length barriers that are non-climbable and anti-throw, and that allow for safer and greater use of the upper spaces in atriums.

To achieve similar outcomes with a heavier material (e.g. glass) would come with higher requirements for labour, material volumes, transport and handling.

An example is the indoor atrium barrier at Monash University in Melbourne, which was initially planned in glass but switched to vertical wire cables.

There are various other high-efficiency features and benefits of Jakob stainless steel wire materials. These include:

- No need for a sub-frame – again reducing volume of materials for projects.

- Excellent longevity (25 years or more) – reducing the need for replacements.

- Low maintenance and cleaning requirements – reducing ongoing costs.

- Lightweight and quick to install – some Webnet barriers are be installed within a few weeks.

- Potential for reduced lighting and HVAC needs – e.g. where the transparency of the material allows for indoor barriers that facilitate natural light entry and airflow. An example is the NSW Rugby Union Centre, where the lightweight Webnet barriers throughout help keep the internal spaces airy and full of natural light.

Building processes and methods

Every additional process in a project has the potential to increase emissions and environmental impact.

To this end, we do much of the work in our projects off-site. This makes for a very efficient installation process, and it helps prevent interruptions.

Take the atrium barrier at Northern Beaches Hospital for example. In this project, we did the bulk of the work off-site, which sped up installation time and allowed the hospital to continue work as usual.

We can also design Webnet barriers to work with existing structures. This approach avoids the need for a secondary structure and helps reduce material volumes.

It’s a combination of factors involving materials and methods that makes stainless steel tensile installations so sustainable. Call us to find out more!